Making the Case for Air Dispersion Modeling

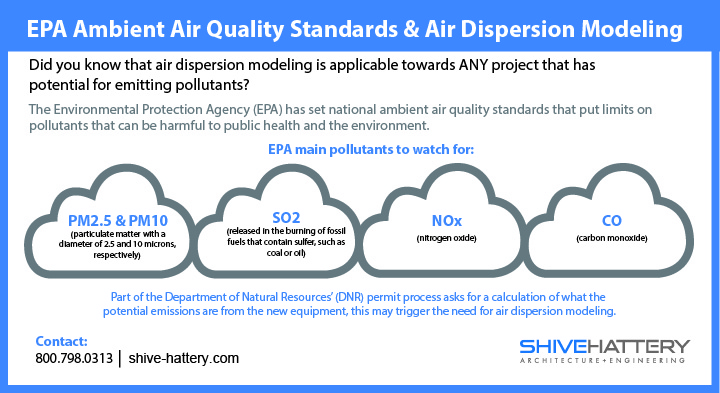

Anything that emits a pollutant should be evaluated for permitting before being installed in a facility.

Anything that emits a pollutant should be evaluated for permitting before being installed in a facility.

The Environmental Protection Agency (EPA) has set national ambient air quality standards that put limits on pollutants that can be harmful to public health and the environment. The main pollutants are:

· PM2.5 and PM10 (particulate matter with a diameter of 2.5 and 10 microns, respectively)

· SO2 (released in the burning of fossil fuels that contain sulfur, such as coal or oil)

· NOx (nitrogen oxides)

· CO (carbon monoxide)

And since part of the Department of Natural Resources’ (DNR) permit process asks for a calculation of what the potential emissions are from the new equipment, this may trigger the need for air dispersion modeling.

What is Air Dispersion Modeling

National ambient air quality standards are set to protect public health. Air dispersion modeling takes a certain data set and projects whether the amount of pollutants emitted by a new project at an established facility will stay within the EPA’s ambient air quality standards. It takes into consideration:

· Five years of meteorological data for the area

· Terrain data

· Building downwash (air will move differently around buildings and over terrain)

· The stack characteristics from the manufacturer

· Emission unit information and building drawings from the facility

· The location of the stack

The modeling software will then show where the worst-case scenario concentration of pollutants would be. If the model is below the EPA’s significant impact level, then the project is given the green light. Full facility modeling is done if the project exceeds the significant impact level. If the emissions will be too close or over the standard, then changes will need to be made to the project’s design. The stack may need to be moved or made taller to help with dispersion and reduce the concentration of pollutants a person may be exposed to.

When Air Dispersion Modeling is Required

The need for air dispersion modeling is evaluated during the permitting process.

1. If emissions are over the significant emission rate, the project requires dispersion modeling.

2. If a facility has done dispersion modeling in the past and the results were too close to the EPA’s ambient air quality standard, then the DNR will determine that any project going forward that emits that pollutant will have to conduct full-facility modeling to prove that the new project won’t cause the facility to exceed the standard.

3. Regulatory agencies can also require dispersion modeling to meet federal requirements like the SO2 Data Requirements Rule or if monitors suggest there is an area of concern.

Making the Case for Air Dispersion Modeling

While air dispersion modeling is frequently required for industrial and higher education projects, it is applicable towards any project that has potential for emitting pollutants – and not all design teams may be aware of the need for it.

Case Study 1: A University Installs New Generators

At one facility, a project installing new generators that exceeded 400 horsepower triggered the need for a permit from the Iowa DNR. While the generators themselves met the EPA’s New Source Performance Standard (NSPS) for generators, the new units were going to be put in an area that was emission unit dense. This triggered an opportunity to educate the design team on the need for modeling.

Since the building was already very tall, Federal Aviation Administration (FAA) rules on building heights would not allow for increased stack heights in this case. Modeling was done to test whether moving the stacks to nearby buildings or switching the generators to non-emergency instead of emergency (which has lower standards) would work. When both of these solutions failed to achieve the necessary results in modeling, it was decided to move the generators to a separate location with fewer neighboring emission units.

Benefit: Air dispersion modeling helped to identify an unexpected, but beneficial design change which kept the project on track.

Case Study 2: A Hospital Converts its Coal-Fired Power Plant to a Natural-Gas Plant

A hospital purchased a coal-fired power plant that provided its steam and wanted to convert it to natural-gas. The coal boilers were immediately shut down and four temporary natural-gas boilers brought in. In the meantime, four permanent natural-gas boilers were being built at the location. While this was going on, the hospital needed to maintain its steam, but modeling showed that the facility would exceed air quality standards with four boilers operating at once.

Air dispersion modeling was used to determine which combinations of two boilers operating at once would meet the standards. Some combinations were below standards, but others exceeded them, mostly dependent on each boiler’s proximity to the hospital campus. Once the correct combinations were found, the facility was able to send steam to the hospital while staying within air quality standards.

Benefit: Air dispersion modeling efficiently and effectively tested a number of design solutions to determine what would be best for the hospital, meet air quality standards, and not disrupt patient service and care.

Benefits of Modeling: Keeping Your Projects Onward and Upwards

Manufacturers have responded to stricter EPA air quality standards by making equipment that emits fewer pollutants. However, new projects many times combine with older equipment which could impact overall levels of pollution.

Air dispersion modeling smooths the pathway to DNR permits for these projects. It also gives you peace of mind that your facilities are in compliance with federal air quality rules and ultimately helps keep your projects moving forward without delay.