3D Scanning Gives You Power to Maintain Substations at Your Fingertips

Some of the benefits include...

Some of the benefits include...

An outage has occurred at a remote utility substation. A crew is sent out early in the morning to make the long drive to the site. Once there, the problem is not readily apparent. Since it is an older substation, there are no drawings available, so the crew spends time investigating the equipment. Once they discover the problem, they drive back to the power station, locate the part needed, and then head back to the substation.

While the repair was successful, the problem caused a power interruption to local businesses and kept a crew busy for two days, much of that in travel time.

Now imagine the same scenario, but the utility company has recently had a 3D scan done of the substation. The company, before sending out a repair crew, was able to go to its 3D model – which contained all the measurements and equipment – and discover the problem. Therefore, the crew is sent out with the necessary part and is able to make the fix and restore power more quickly with less field work time.

Having a 3D scan of your substations gives you a workable model of what exists in the field at your fingertips.

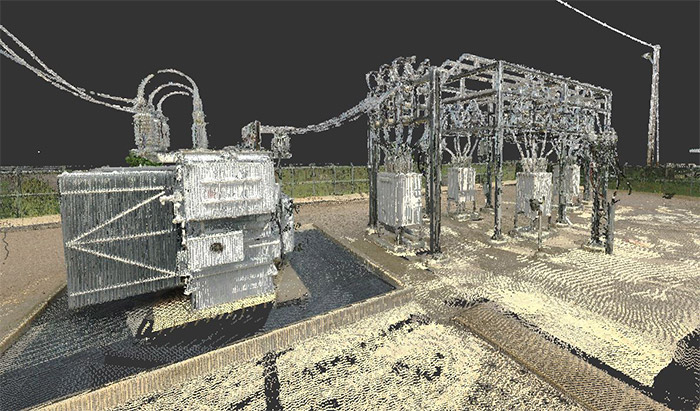

3D scanning uses a sophisticated camera that takes 3D images to create point clouds of data that can be turned into a digital model. The 3D models contain very precise measurements of equipment that you couldn’t touch otherwise while it’s energized.

Clients can use 3D models to be proactive and develop maintenance programs for their substations or as a tool when emergencies/problems arise. Some of the benefits include:

A 3D model can be available to companies a week or two after scanning the substation. There is also a big advantage to doing several at once – it allows a streamlined process by planning out a route to the substations so that more can be scanned each day.